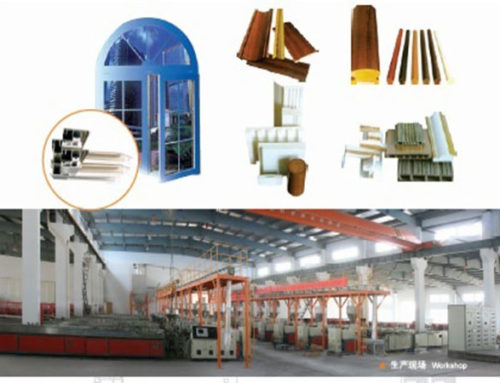

Project Description

PVC Sheet Extrusion Line

The main advantages are:

1) Energy savings

2) Less space needed

3) Simple logistic management

4) Substantial cost savings (investment, management …)

5) Formulations adjustable in-line

6) Maintain a proprietary in-house manufacturing process

LIANGUAN is a specialist in offering turn – key solution for the entire process plant.

The typical layout for a profile system includes the following modules:

1. Automatic feeder

2. Twin screw co-rotating extruder for excellent mixing and high production rate

3. Melt Pump – for steady pressure generation

4. Die Head – for shaping your desired profile

5. Calender for sizing and cooling the sheets

6. cooling roller unit

6. Haul off

7. Cutter unit

8. Stacker

As you need, we also can manufacture PP/PE lines for you

The typical layout for a profile system includes the following modules:

1. Automatic feeder

2. Twin screw co-rotating extruder for excellent mixing and high production rate

3. Melt Pump – for steady pressure generation

4. Die Head – for shaping your desired profile

5. Calender for sizing and cooling the sheets

6. cooling roller unit

6. Haul off

7. Cutter unit

8. Stacker

As you need, we also can manufacture PP/PE lines for you