Project Description

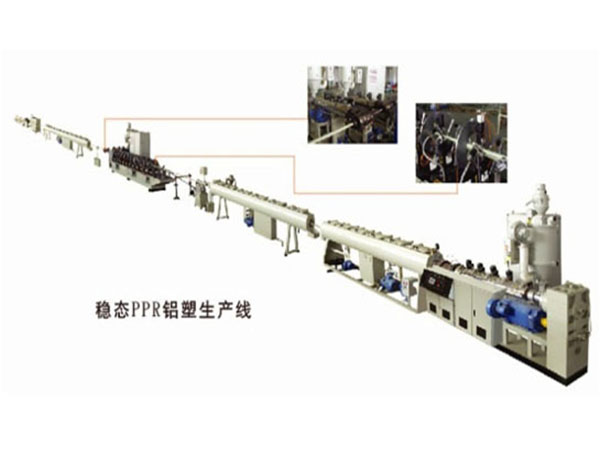

Production Line for Stable PPR Pipes with Aluminum

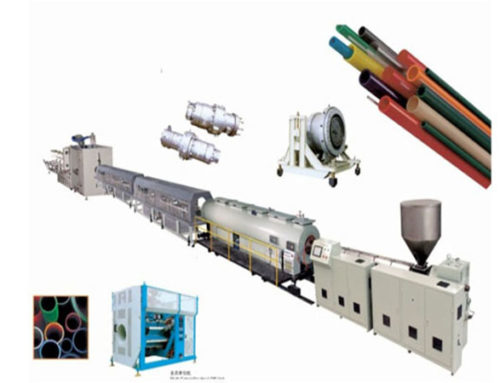

Extruder:

It has adopted the famous brand speed-regulating systems,

shielding double-pole mixed PP-R specialized screw and the cylinder which has

channels in it. Diameter setting part: It has adopted vacuum negative pressure

setting and recycled water cooling and it is made of stainless steel.

Drawing part: It has adopted pneumatic gripping and the famous brand frequency

control systems which enable the stable drawing of the pipes.

Molding part: It has adopted perfect molding and compounding technology which guarantee the

perfect combination of pipes.

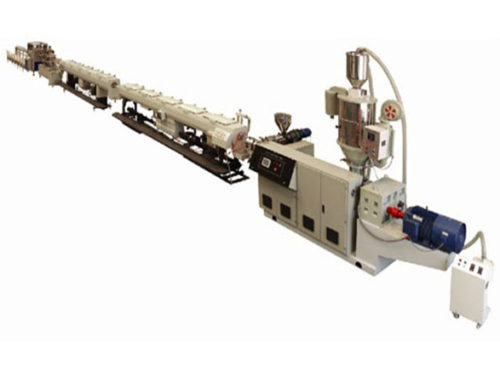

Automatic control: By using PLC programmable computer control system from Mitsubishi of Japan, it can

make the extruding quantity, drawing, compounding and molding, cutting all controlled by programs, so that the whole production line is a closed circle.

control systems which enable the stable drawing of the pipes.

Molding part: It has adopted perfect molding and compounding technology which guarantee the

perfect combination of pipes.

Automatic control: By using PLC programmable computer control system from Mitsubishi of Japan, it can

make the extruding quantity, drawing, compounding and molding, cutting all controlled by programs, so that the whole production line is a closed circle.