Project Description

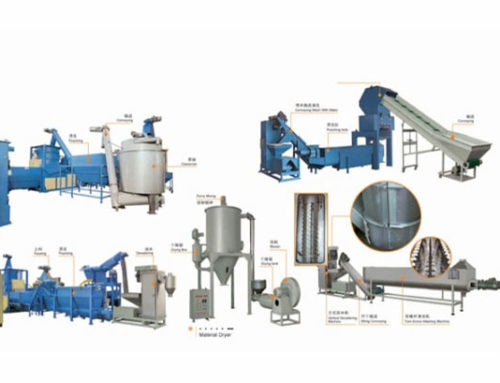

PE/PP Granulating Line

PP Granulating line , PE recycling system consist of :

Also see PP Granulating &Recycling process–Viedo Display

1. Agglomerator: press the materials for down steam feeding into extruder

2. Screw feeder: tansport the pressed materials to the extruder

3. Force feeder: will feed the materials into the extruder continously

4. Extruder: equipped with pre-heaters, filtrating screen and venting hole, driven by frequency conversion system, it could extrude good quality melt with high capacity

5. Water-ring pelletizer: flat mould, the knIves close to mould face, stable pelletzing can be realized

6. Dewatering machine: screen out the water with a high speed centrifigue

7. Blowing system: dry the pellets as well as convey the pellets to the cyclone silo

8. Cyclone silo: for separation of dust from fine material to achieve a better quality final products.

We also supply other plastic recycling machines: PET bottle washing line, double rank recycling system, plastic shredders, eps melting machines.

4. Extruder: equipped with pre-heaters, filtrating screen and venting hole, driven by frequency conversion system, it could extrude good quality melt with high capacity

5. Water-ring pelletizer: flat mould, the knIves close to mould face, stable pelletzing can be realized

6. Dewatering machine: screen out the water with a high speed centrifigue

7. Blowing system: dry the pellets as well as convey the pellets to the cyclone silo

8. Cyclone silo: for separation of dust from fine material to achieve a better quality final products.

We also supply other plastic recycling machines: PET bottle washing line, double rank recycling system, plastic shredders, eps melting machines.